About

| Encoder Type |

Rotary

|

| Shaft Type |

Solid

|

| Usage/Application |

Industrial

|

| Color |

Black

|

| Power Supply Voltage |

STANDARD

|

| Multi Turn |

NO

|

| Single Turn |

YES

|

| Storage Environment |

AS PER USE

|

| Minimum Order Quantity |

1000 टुकड़ा

|

Consumer Electronics: Power switches in radios, flashlights, and toys.Industrial Equipment: Control switches for machinery and equipment.Automotive: Control switches for lights, wipers, and other systems.Telecommunication Devices: Signal routing and selection.Computers and Peripherals: Mode selection, reset switches, and power control.

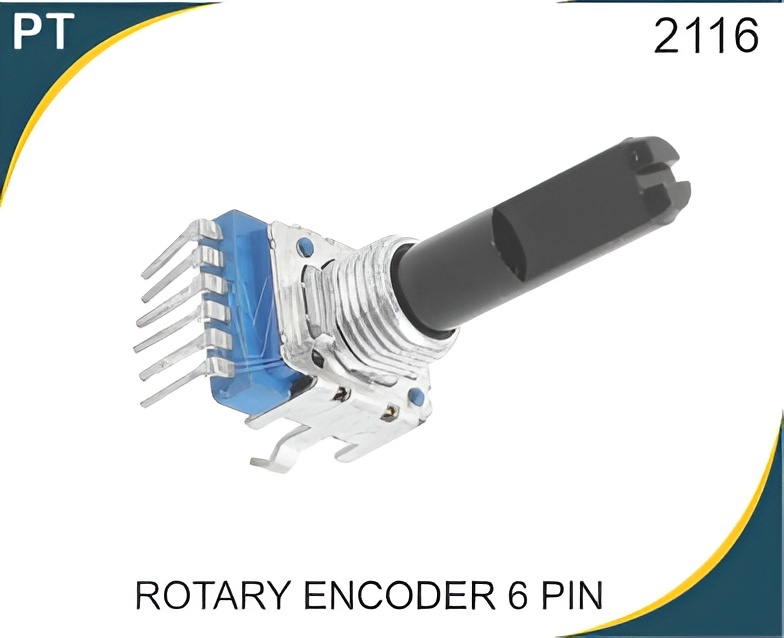

Precision and ReliabilityEngineered for high accuracy, this rotary encoder provides 20 distinct positions with robust contact and insulation resistance, ensuring dependable data output for sensitive control systems. Its continuous 360 rotation and precise detent mechanism make it ideal for precise adjustment tasks.

Versatile ApplicationsSuitable for industrial automation, audio equipment, and robotics, the encoders compact cylindrical shape and PCB mount compatibility allow flexible integration into diverse environments. Its IP40 rating offers basic protection, and the 6-pin solder type connection simplifies installation.

Durability and ComplianceWith an electrical life of up to 30,000 cycles and compliance with RoHS and lead-free standards, this component ensures longevity and environmental responsibility. Its nickel-plated finish adds to its corrosion resistance, promising sustained fidelity even in demanding conditions.

FAQs of Rotary Encoder 6 Pin:

Q: How is the Rotary Encoder 6 Pin installed in a circuit?

A: The encoder features a 6-pin solder type connection and is designed for PCB mounting. Simply align the pins with the PCB ports and solder firmly in place, ensuring reliable electrical contacts for output signal channels and the integrated push button switch.

Q: What are the practical benefits of using a 20-position rotary encoder in automation systems?

A: With 20 detents per revolution and high accuracy, this rotary encoder allows for precise control and reliable feedback in automation tasks. It enables accurate incremental input, improving responsiveness and adjustment fidelity in industrial, audio, and robotic systems.

Q: When should I use the integrated push button switch on this encoder?

A: The integrated push button switch is ideal for applications requiring dual-input options, such as confirming selections or triggering secondary actions within user interfaces or control systems. It enhances versatility in process control and machine operation design.

Q: Where can this rotary encoder be utilized for optimal performance?

A: Its design caters to industrial automation, audio processing equipment, and robotics. You can implement it in machinery controls, sound mixers, or robot position feedback modules, thanks to its high accuracy, low contact resistance, and robust construction.

Q: What process should be followed for maintaining environmental compliance with this product?

A: The encoder is RoHS compliant and lead-free. To maintain environmental standards, ensure that disposal procedures adhere to electronic recycling practices and avoid exposure to temperatures outside the storage range of -30C to +80C.

Q: How do the dual output channels (A & B) improve signal processing?

A: The quadrature output (Channels A & B) provides precise digital incremental signals, allowing for accurate direction and pulse counting. This feature enhances feedback systems by enabling both position tracking and rotational direction sensing.