Rotary Encoder 3 Pin

Price 450 INR/ Piece

Rotary Encoder 3 Pin Specification

- IP Rating

- Not Rated

- Overheating Protection

- NO

- Efficiency

- High for signal transmission

- Mounting Type

- Panel Mount

- Operating Temperature

- -20C to +70C

- Humidity %

- 95%

- Feature

- Push Button Function, 360 Rotation, Detent Option

- Shape

- Cylindrical

- Connector Type

- 3 Pin PCB

- Insulation Material

- Plastic

- Surface Finish

- Nickel Plated

- Product Type

- Rotary Encoder

- Application

- Position and direction detection, Arduino/Raspberry Pi Projects

- Protection Level

- Standard

- Frequency (MHz)

- DC Only

- Rated Voltage

- 5V DC

- Energy Consumption

- Low

- Output Type

- Digital

- Color

- Silver and Blue

- Dimension (L*W*H)

- 20mm x 12mm x 15mm

- Weight

- 10 grams

- Phase

- Single Phase

- Input Voltage

- 5V DC

- Size

- Shaft Length 20mm, Diameter 6mm

- Material

- Metal and Plastic

- Connection Type

- Pin-insertion

- No Of Poles

- 3

- Insulation Resistance

- >=100M at 500V DC

- Detent

- Yes, tactile feedback

- RoHS Compliant

- Yes

- Torque

- 0.1-0.5 Ncm

- Operating Life

- Up to 30,000 cycles

- Max Shaft Load

- 1.5 kgf

- Contact Resistance

- 100m

- Resolution

- 20 pulses per revolution (PPR)

- Switch Type

- Momentary Push Button

Rotary Encoder 3 Pin Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About Rotary Encoder 3 Pin

| Encoder Type |

|

| Shaft Type |

|

| Usage/Application |

|

| Color |

|

| Hollow Shaft Diameter |

|

| Power Supply Voltage |

|

| Multi Turn |

|

| Operating Temperature Range |

|

| Output Circuit |

|

| Single Turn |

|

| Storage Temperature Range |

|

| Features |

|

| Maximum Rotation Speed |

|

| Weight (packed state) |

|

| Cable And Connector |

|

| Minimum Order Quantity |

|

Durable and Reliable Structure

This rotary encoder is built to withstand up to 30,000 cycles, thanks to its robust combination of metal and plastic materials. Its 360 rotation, sturdy shaft, and panel mount design ensure reliable and seamless integration into various applications, including prototyping and industrial usage.

Versatile and User-Friendly Design

With its three-pin output, tactile detent, and integrated momentary push button, the encoder offers effortless operation and precise feedback. Its low torque and compact size make it ideal for embedded electronics projects, while the digital output simplifies connection to microcontroller platforms such as Arduino or Raspberry Pi.

FAQs of Rotary Encoder 3 Pin:

Q: How do I connect the Rotary Encoder 3 Pin to an Arduino or Raspberry Pi?

A: You can connect this rotary encoder to an Arduino or Raspberry Pi by inserting its three pins into the corresponding PCB connectors. Typically, two pins are used for signal (A and B channels) and one for ground. Consult the devices datasheet for exact pin configuration and connection diagrams.Q: What is the main benefit of the detent and tactile feedback feature?

A: The detent and tactile feedback provide physical indication at each pulse, improving operation precision and user experience. This is especially useful for applications that require accurate incremental adjustments or menu navigation.Q: Where can this rotary encoder be used most effectively?

A: This encoder is ideal for use in applications such as position and direction detection, robotics, industrial controls, and interactive projects using Arduino or Raspberry Pi platforms. Its compact design and durability make it suitable for both prototyping and final products.Q: When should I consider replacing the rotary encoder?

A: The rotary encoder should be replaced after reaching its operating life of up to 30,000 cycles, or if you notice increased contact resistance or unreliable signal transmission during operation.Q: What safety precautions should be taken during usage?

A: Operate the encoder within its rated voltage of 5V DC and within the specified temperature range (-20C to +70C). Avoid subjecting the shaft to loads beyond 1.5 kgf and ensure the humidity does not exceed 95%. Since the device is not rated for IP protection, keep it away from high-moisture or dusty environments.Q: How does the momentary push button function enhance usability?

A: The integrated momentary push button allows an additional digital input, supporting actions such as reset, selection, or confirmation within user interfaces, enhancing device functionality without needing extra components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Potentiometer And Slides Category

15 MM D-Cut 5 Pin Metal Enroll

Price 35 INR / Piece

Minimum Order Quantity : 1000 Pieces

Dimension (L*W*H) : 15 mm diameter

Color : Silver

Weight : Approx 30 grams

Application : Electrical switch, lock mechanisms, industrial control panels

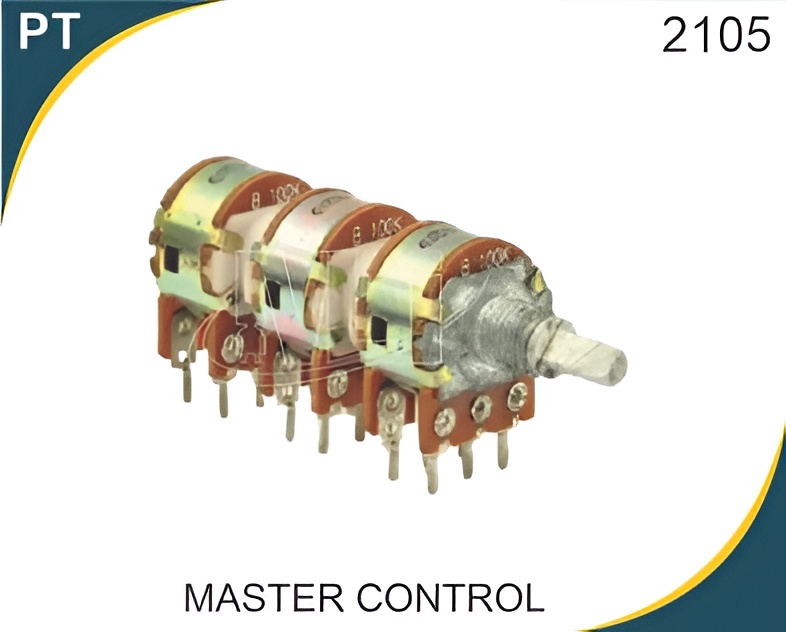

IMPORTED Mild Steel MASTER CONTROL, For Railway Siding

Price 300 INR / Piece

Minimum Order Quantity : 1000 Pieces

Dimension (L*W*H) : 520mm x 340mm x 145mm

Color : Grey & Black

Weight : Approx. 45 kg

Application : Railway Siding

Potentiometer METAL KNURING 20 MM S

Price 15 INR / Piece

Minimum Order Quantity : 1000 Pieces

Dimension (L*W*H) : Diameter 20 mm, Standard Shaft Length

Color : Silver (Metal Knurled), Black (Knob)

Weight : Approx. 15 grams

Application : Volume Control, Electronic Circuits, Audio

POTENTIOMETER D-CUT 5MM

Price 20 INR / Piece

Minimum Order Quantity : 1000 Pieces

Dimension (L*W*H) : Diameter: 17mm, Shaft length: 20mm, Shaft diameter: 5mm Millimeter (mm)

Color : Black knob with silver shaft

Weight : Approx. 7 grams Grams (g)

Application : Electronic circuit adjustment, volume control

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry