9.5 MM PITCH 4 PIN BARRIER TERMINAL CONNECTOR

Price 15 INR/ Piece

9.5 MM PITCH 4 PIN BARRIER TERMINAL CONNECTOR Specification

- Voltage Rating

- 300V

- Temperature

- -40C to +105C

- Male End Type

- Pin

- Material

- Thermoplastic with brass screw contacts

- Application

- PCB, power distribution, electrical connection

- Capacity

- 24A max

- Connector

- Barrier terminal block

- Female End Type

- Screw clamp

- Connector Type

- Barrier Terminal Connector

- Flame Resistance Level

- UL94V-0

- Sheild

- No

- Number of Conductor

- 4

- Color

- Black

- Insulation

- Polycarbonate body

- Wire Gauge

- 14-22 AWG

- Pitch

- 9.5mm

- Mounting Type

- PCB mount

- Number of Pins

- 4

- Contact Plating

- Tin over nickel

- Withstand Voltage

- 2000V AC/1 min

- Torque

- 0.5 Nm max

- Screw Type

- Steel, nickel plated

- Termination Style

- Screw terminal

- Housing Material

- Thermoplastic (UL94V-0 rated)

9.5 MM PITCH 4 PIN BARRIER TERMINAL CONNECTOR Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About 9.5 MM PITCH 4 PIN BARRIER TERMINAL CONNECTOR

| Material |

|

| Usage/Application |

|

| Size |

|

| Brand |

|

| Packaging Size |

|

| Number Of Holes |

|

| Number Of Piece |

|

| Minimum Order Quantity |

|

- Applications:

- Used in battery connections, LED lighting, computer hardware, and hobby electronics.

- Suitable for compact and lightweight electronic devices.

- Advantages:

- Reliable and secure connections with locking mechanisms to prevent disconnection.

- Compact and space-saving design.

- Easy to assemble and disassemble without special tools.

Durable Construction for Reliable Connections

Built with a flame-retardant thermoplastic housing and plated brass screw contacts, this barrier terminal connector ensures both safety and durability. Its steel, nickel-plated screws and robust design are perfect for demanding environments requiring long-term reliability.

Easy Installation and Flexible Mounting

The connectors PCB mount design and screw terminal style provide straightforward installation without the need for specialized tools. It fits a wire range of 1422 AWG, and the screw clamp mechanism allows for secure, quick wire connections every time.

Wide Range of Applications

Whether used in industrial automation, power distribution panels, or general electronics, this barrier terminal connector adapts to multiple usage scenarios. Its UL94V-0 rated insulation and high current capacity make it suitable for both high and low power needs.

FAQs of 9.5 MM PITCH 4 PIN BARRIER TERMINAL CONNECTOR:

Q: How do I install the 9.5 MM Pitch 4 Pin Barrier Terminal Connector on a PCB?

A: Simply align the connector pins with the corresponding holes on your PCB and solder them in place. Then, insert your stripped wire ends (1422 AWG) into the screw terminals and tighten the screws to secure the connection.Q: What are the main benefits of using this barrier terminal connector?

A: This connector offers high current and voltage ratings (24A max, 300V), excellent flame resistance (UL94V-0), and a secure screw clamp termination. Its robust thermoplastic housing and reliable brass contacts ensure stable electrical performance in critical applications.Q: When should I choose this connector over other terminal blocks?

A: Opt for this connector when you need a secure, high-capacity solution for power or signal distribution on PCBs, especially where flame resistance and easy wire changes are important.Q: Where is this connector typically used?

A: Its commonly found in power distribution panels, industrial automation systems, electrical control boards, and other PCB-based equipment requiring reliable barrier-type terminal connections.Q: What is the torque specification for tightening the screws?

A: The maximum recommended torque for the steel, nickel-plated screws is 0.5 Nm, ensuring firm wire grip without damaging the connector.Q: How does the screw clamp termination style work?

A: The screw clamp style lets you insert stripped wire ends directly under the terminal screw. By tightening the screw, you press the wire securely against the metal contact for a strong, durable electrical connection.Q: What makes the connectors materials advantageous?

A: With a UL94V-0 rated thermoplastic body and tin-over-nickel plated contacts, the connector is flame-retardant and corrosion-resistant, offering enhanced safety and long-term reliability in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BARRIER & JST CONNECTORS Category

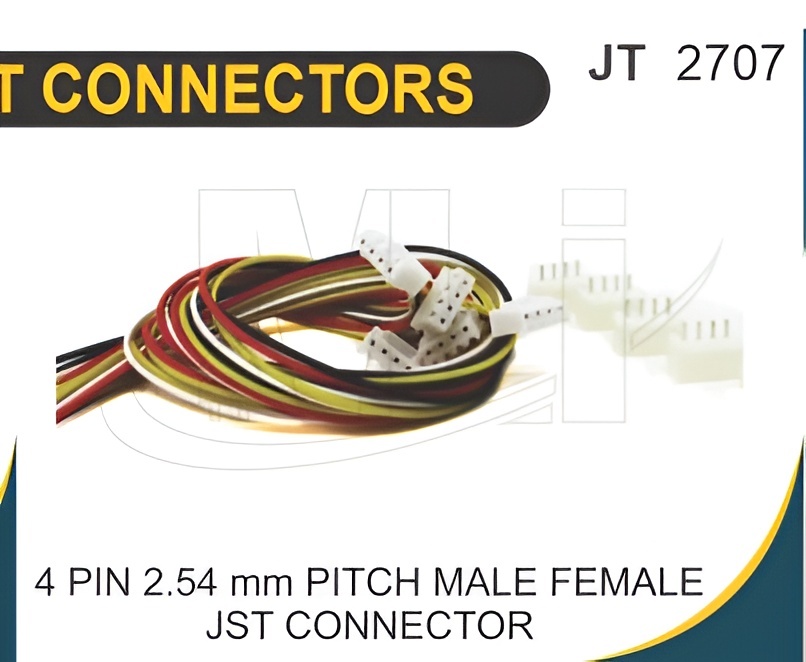

4 PIN 2.54 MM PITCH MALE FEMALE JST CONNECTOR

Price 15 INR / Piece

Minimum Order Quantity : 1000 Pieces

Color : Other, White / Black (Depends on cable)

Material : Other , PBT / PA66 (Connectors), Copper Tinned (Wire)

Temperature : 25C to +85C

Flame Resistance Level : UL94V0

10 PIN 2.54 MM PITCH MALE FEMALE JST CONNECTOR

Price 15 INR / Piece

Minimum Order Quantity : 1000 Pieces

Color : Other, Black (Housing), Multicolor Wires

Material : Other , Nylon (Connector Housing), Tinplated Phosphor Bronze (Contacts)

Temperature : 25C to +85C

Flame Resistance Level : UL 94V0

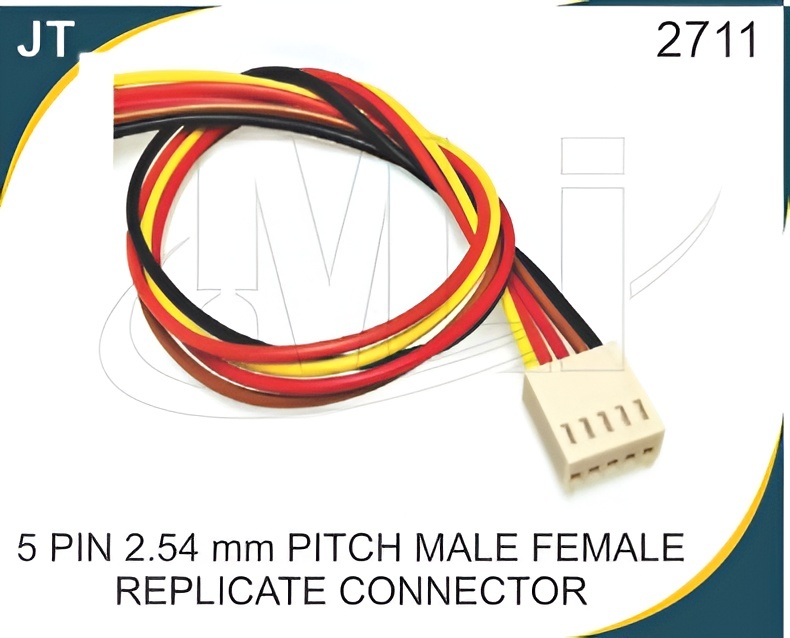

5 PIN 2.54 MM PITCH MALE FEMALE REPLICATE CONNECTOR

Price 10 INR / Piece

Minimum Order Quantity : 1000 Pieces

Color : Black

Material : Other , Phosphor Bronze, Tin Plated

Temperature : 25C to +85C

Flame Resistance Level : UL94V0

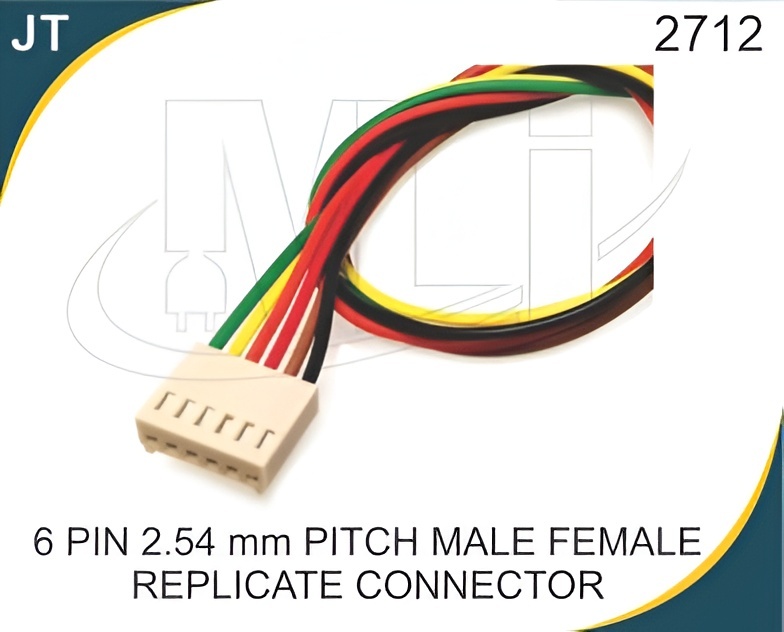

6 PIN 2.54 MM PITCH MALE FEMALE REPLICATE CONNECTOR

Price 15 INR / Piece

Minimum Order Quantity : 1000 Pieces

Color : Black

Material : Other , Contact: Phosphor Bronze; Housing: PA66 (Nylon)

Temperature : 20C to +85C

Flame Resistance Level : UL94V0

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry